Products

ENERCON Flame Treater

Enercon Flame Plasma Technology

Powerful Flame Treatment with Precise Control

Improve adhesion on plastics, glass, metals and more.

Enercon Flame Plasma Treaters offer safe and reliable surface treatment for any flat or dimensional surface. Our advanced combustion control architecture and unique high velocity power burner ensures powerful and repeatable surface treating results.

- Improves Adhesion Of Inks, Coatings & Adhesives

- Long Lasting, Uniform, High Treatment Levels

- Fail Safe Design

- Advanced Control Ensures Reliability

- Efficient Surface Decontamination And Polishing

Clean, etch and functionalize

Clean Surfaces

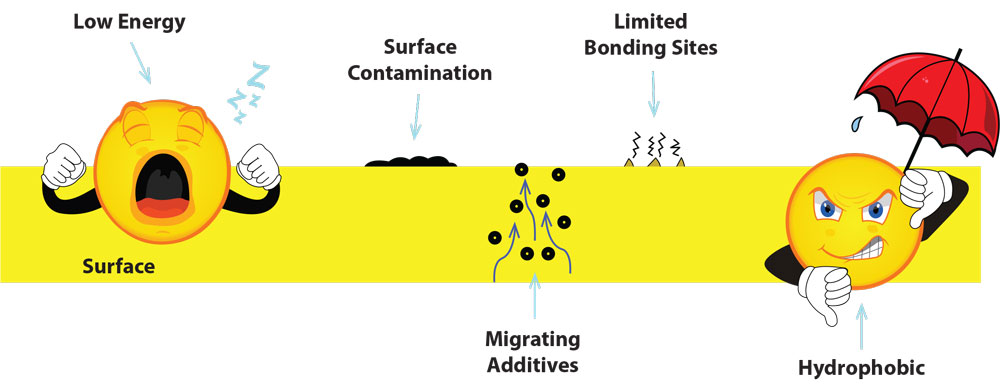

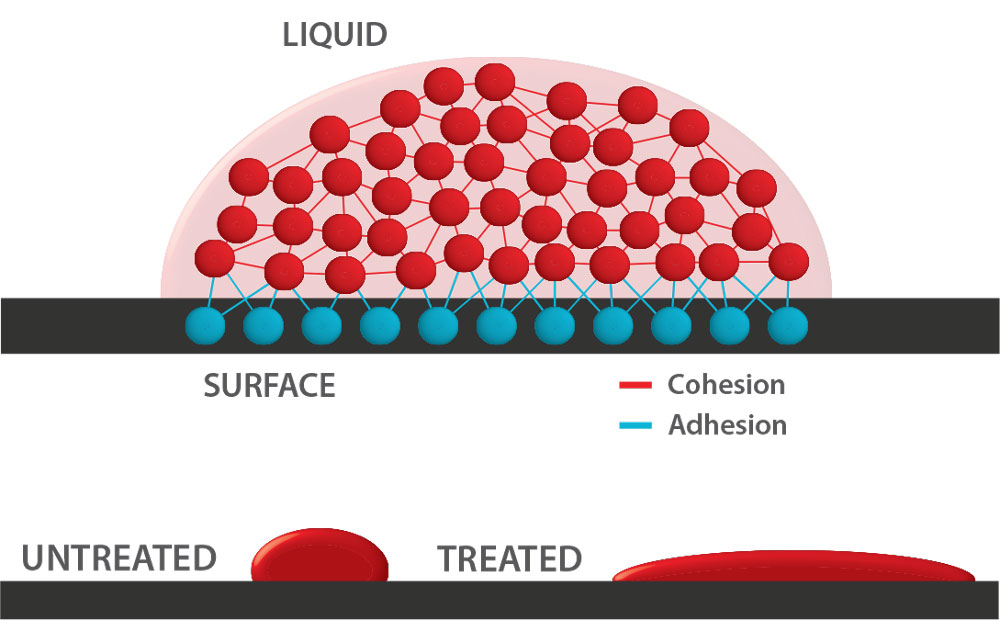

Flame plasma treatment removes organic and inorganic impurities & contaminants from the surface. Flame plasma species react with the surface by vaporizing low molecular weight contaminants, exposing a clean surface and improving adhesion.

Etches Surfaces

Micro etching of a polymer surface is accomplished as charged ions, neutral atoms and radicals, in both the plasma forming gas and the reactive process gas, bombard the surface.

Increasing surface area creates more bonding sites which promotes adhesion success.

Functionalizes Surfaces

Flame plasma activation or functionalization is the concurrent process of using radicals to break up surface polymer bands to create cross linking of surface molecules.

This process increases polar groups which directly contributes to the surface’s adhesion properties.

PowerFlame™ High Velocity Burner Technology

- High-velocity ports for powerful treatment

- Multiple burner designs for optimal dwell time

- Uniform treatment across entire width of burner

- Eliminates laning or striations

- Brass inserts are easily removed for cleaning

- Variable treat widths including burner deckling